From: Walter Bierwerth, Tabellenbuch Chemietechnik, 11th edition, Verlag EUROPA-LEHRMITTEL, Europe No. 70717, S439 et seq.

Task:

In a mixture of benzene and toluene, the mass fraction of benzene is to be enriched by continuous rectification.

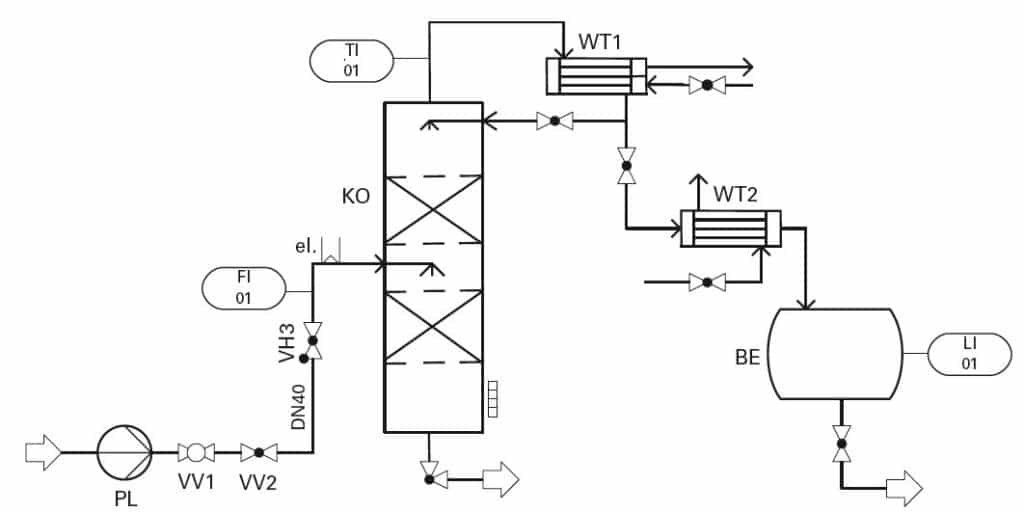

The plant is shown in the flow diagram.

The mixture (pure mixture of two substances, ϑV= 20 °C) has the following composition for separation:

|

Benzene: mass fraction

|

w1 = 25 %

|

|

Toluene:

|

w2 = 75 %

|

Operating specifications:

Desired enrichment: w1 = 0.95 (column head), the sump drain should still contain a maximum of w1 = 0.05 benzene.

|

Flow rate Feed:

|

qV = 80 L/min

|

|

Length of the supply line (straight pipeline sections):

|

L = 15 m

|

|

Height difference feed pump/column feed (geodetic height):

|

z = 4 m

|

Inlet to the column: boiling liquid

Outlet from the head condenser: boiling liquid

Cooling of the distillate in the distillate cooler to ϑ = 40 °C

Cooling water is available with a relatively constant inlet temperature of ϑ = 20 °Cand should not be warmer than ϑ = 30 °C when leaving the system.

The column is operated at normal pressure.

Components to be designed:

Centrifugal pump (feed pump): Required pump capacity via pressure loss in the supply line

mixture preheater (electrical pipe heating, inductive): Required heating power?

Separation column(packed column): required number of theoretical stages according to McCabe-Thiele

Head condenser (shell-and-tube heat exchanger): Required exchange area

Distillate cooler (shell-and-tube heat exchanger): required exchange area

Distillate receiver (horizontal cylindrical buffer tank with dished ends): Level diagram qV = f(h)

Required fittings and other pipeline parts in the feed line:

2 bends (elbows) 90°, R/d = 4

1 Globe valve (DIN valve)

1 shut-off valve (ball valve), 50 % open

1 check valve

1 vortex meter

flow diagram

flow diagram

calculation steps

Determination of the boiling temperature of the feed mixture using the Antoine constants (PROPER)

Determination of the density of the feed mixture p. 121 (PROPER)

Determination of the viscosity of the feed mixture p. 110/111 and p. 75 (PROPER)

Determination of the nominal size for the feed line p. 182 (L1.2)

Calculation of the pressure loss in the planned feed line p. 209 (FDP / NPSH)

Required pump capacity p. 227 f. (NPSH)

Electrical heating of feed inlet to boiling temperature – Required electrical power (BIL)

Calculation of the required number of separation stages for the rectification column p. 256/257 (RKS)

Determination of the required exchange surface of the head condenser (C1 / WTS)

Determination of the required exchange area of the distillate cooler (C1 / KOND)

Level diagram in the distillate receiver (TKL)

Dieser Beitrag ist auch verfügbar auf:

Deutsch (German)

Deutsch (German)