Pmax module incl. Nzul

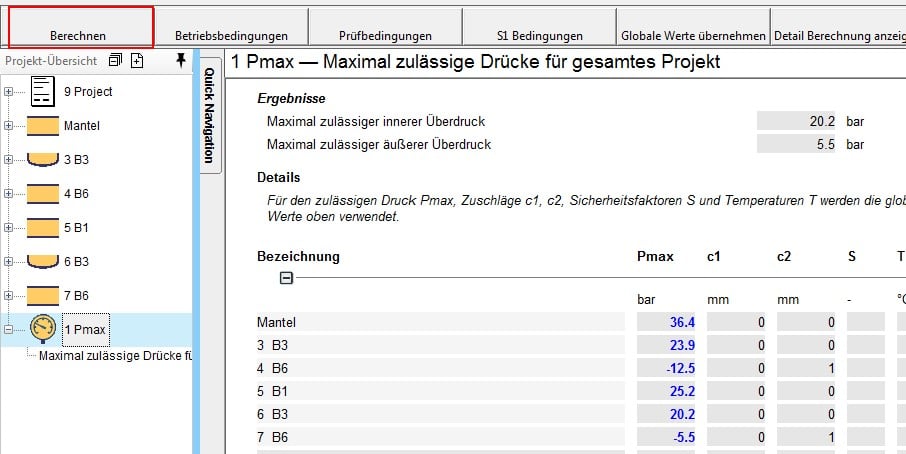

Determination of the maximum allowable working and test pressures.

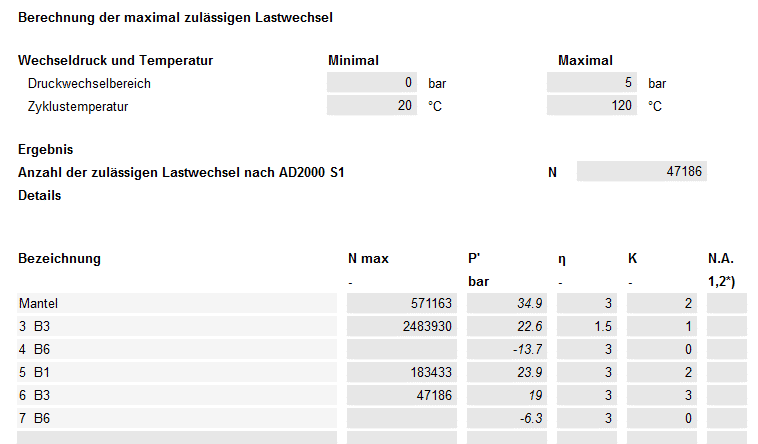

Calculation of allowable load cycles.

For a quick assessment of a pressure device, it makes sense to know the maximum possible operating and test pressure for each device component.

A tabular listing of these values allows a statement about the available reserves and an immediate determination of the weakest, limiting components.

According to the latest standards, the component that limits the pressure under the respective conditions must also be specified.

DIN EN 13445 stipulates that only 500 full load cycles instead of 1000 load cycles according to the AD 2000 data sheets are to be granted to a pressure device without proof.

For pressure equipment, proof of alternating stress can therefore be required very soon.

Pmax calculates the maximum allowable pressure for pressure vessel components in a complete project.

The permissible component pressure can be determined for the states:

- Operating conditions

- Test conditions

- Determination of the fictitious pressure PT

- for load cycle calculation according to S1

- Calculation of arbitrarily defined states, e.g. strong corrosion

The calculation is not limited to a simple pressure calculation; all boundary conditions for this component are checked.

The additional information required for the calculation of the max. allowable operating pressure, test pressure and reference pressure for AD S1 are implemented. It is also possible to set the boundary conditions yourself, e.g. for pressure shock and explosion wave calculations.

The joint efficiency factors for the load cycle calculation are proposed by the program and can be adapted to the circumstances at any time.

The number of allowable load cycles is determined by the Nzul module.

If you click on this video we will play the video, load scripts on your device, store cookies and collect personal data. This enables [Google Ireland Limited, Irland] to track activities on the Internet and to display advertising in a target group-oriented manner. There is a data transfer to the USA, which does not have EU-compliant data protection. You will find further information here.

Jmx0O2lmcmFtZSB0aXRsZT0mcXVvdDtTMSBMYXN0d2VjaHNlbGJlcmVjaG51bmcgbWl0IExWIFNvZnR3YXJlIFByb2dyYW1tc3lzdGVtIEF0bGFzJnF1b3Q7IHdpZHRoPSZxdW90OzY5NiZxdW90OyBoZWlnaHQ9JnF1b3Q7NTIyJnF1b3Q7IHNyYz0mcXVvdDtodHRwczovL3d3dy55b3V0dWJlLmNvbS9lbWJlZC9FNDBXc3FXTVJoQT9mZWF0dXJlPW9lbWJlZCZxdW90OyBmcmFtZWJvcmRlcj0mcXVvdDswJnF1b3Q7IGFsbG93PSZxdW90O2FjY2VsZXJvbWV0ZXI7IGF1dG9wbGF5OyBlbmNyeXB0ZWQtbWVkaWE7IGd5cm9zY29wZTsgcGljdHVyZS1pbi1waWN0dXJlJnF1b3Q7IGFsbG93ZnVsbHNjcmVlbiZndDsmbHQ7L2lmcmFtZSZndDs=

PMAX

PMAX NZUL

NZUL

see also

Dieser Beitrag ist auch verfügbar auf:

Deutsch (German)

Deutsch (German)