Calculation of flanges according to DIN EN 1591 and 13445-3 Appendix G in conformity with the Pressure Equipment Directive

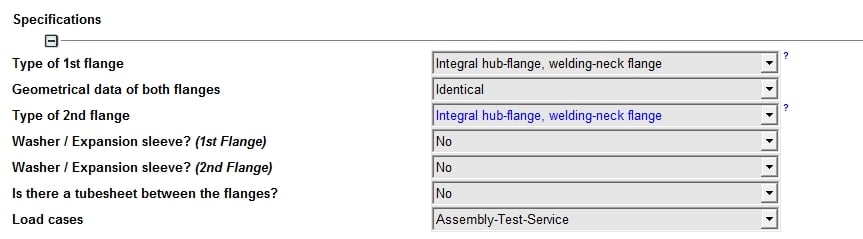

With Module 1591, flange connections of the same or different flanges can be calculated.

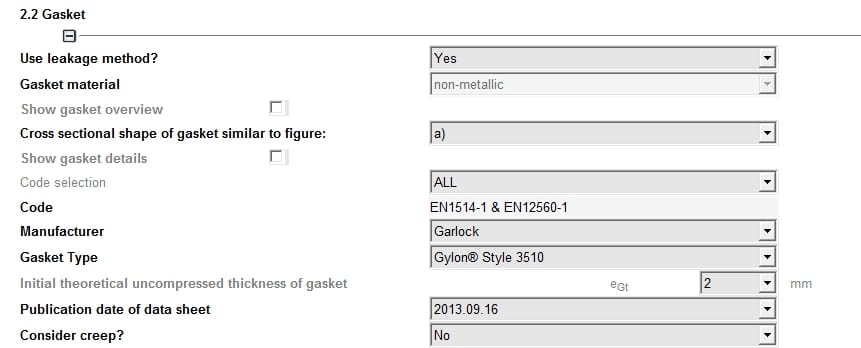

Since issue EN 1591:2011 sealing parameters are specified depending on the leakage rate e.g. according to TA-Luft.

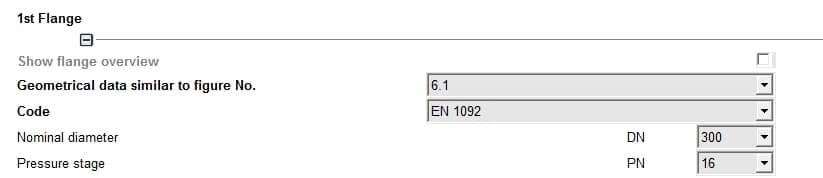

>> By the integrated connection of the module 1591 with the additional module 1092 (steel flanges incl. strength verification) you save the input of the geometry sizes and the gasket characteristic values for the flange calculation.

>> Via a connection to an extensive, constantly extended gasket database based on manufacturer data, gasket parameters can be comfortably used in the calculation. Gasket dimensions are also provided.

>> Corrosion allowances c2 can be considered in addition to the standard for the flange thickness, the inside diameter and the shell thickness. This allows the calculation for the corroded and non-corroded condition to be performed. It is possible to specify the material delivery standard or to enter any user-defined corrosion allowance c2.

Program features

The program contains the complete calculation specification according to DIN EN 1591-1 or the corresponding section of DIN EN 13445-3/G.

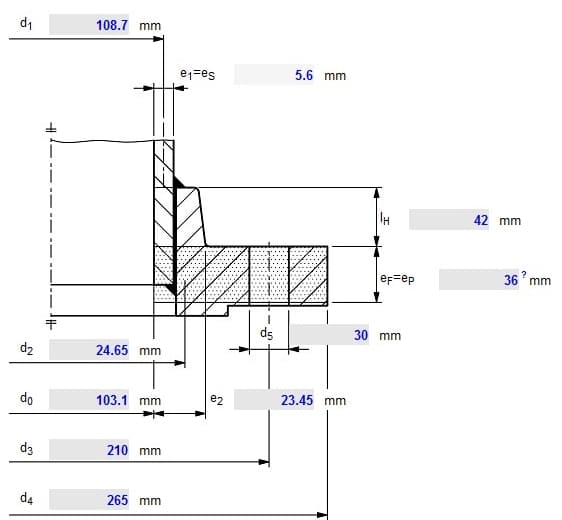

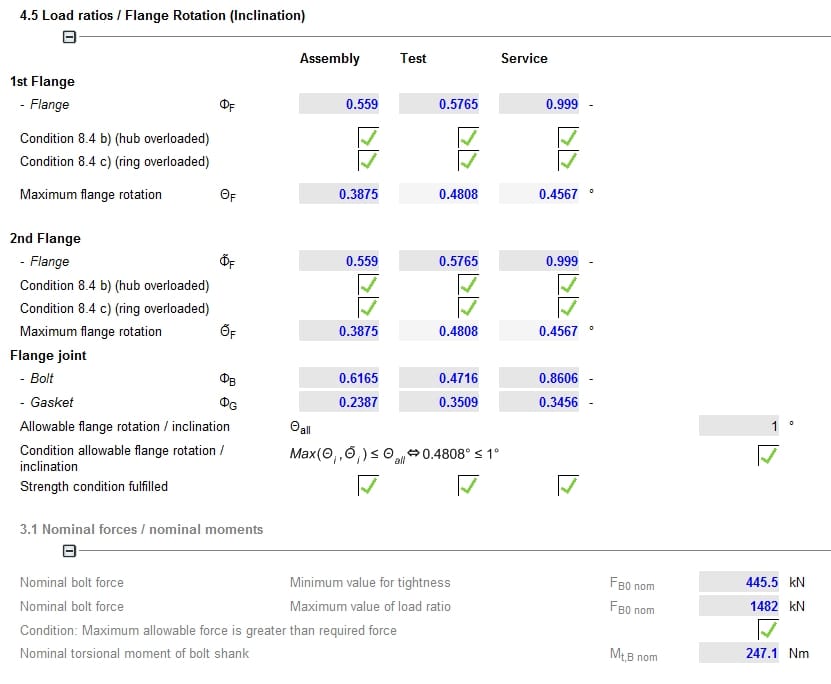

It enables the calculation of weld-on, welding neck, blind and loose flanges. The calculation method takes into account the elasticity of the connected shell, the thermal expansion between flange and bolts and the effective gasket surface and calculates the required assembly torque for the bolts. In order to evaluate the load cases, the loads for flange, bolts, gasket and loose flange are determined.

By integrating databases, the required data for flange, screw and gasket geometry as well as the gasket characteristics of all gasket materials can be retrieved from the stored tables in accordance with the manufacturer’s specifications and DIN EN 1591-2.

After entering the nominal diameter, the nominal pressure and, if necessary, the operating temperature, the data for the flange and gasket geometry from the tables contained are directly available in the flange calculation (Module 1591). Also stored are the temperature-dependent gasket parameters for all gaskets in accordance with Part 2 of DIN EN 1591.

Differences to previous calculation methods according to AD 2000 / ASME

EN 1591 also takes into account

- the non-linear elastic behaviour of the gasket

- the forces from different thermal expansions of the flange and bolts

- additional external axial forces and moments

- the influence of the number of assemblies on the gasket or the tightness of the connection

- the elastic supporting effect due to the connected shell

- the tensioning of bolts, flange and gasket in the calculation of the loads

- Several subsequent load conditions Operation, testing and assembly when calculating the bolt torque

- more accurate calculation models for the elastic behaviour of flange, bolts, shell and gasket.

The tightening method can be taken into account in the calculation (e.g. with wrench, impact wrench, torque wrench with or without measuring device). This allows the tightness of a flange connection to be tested in practice under various load conditions. A flange connection mounted with a torque wrench, for example, requires lower bolt forces than when tightened by hand. The utilization rate of the flange connection decreases accordingly.

Easy data input

The required data are entered via a single input mask. The program therefore provides a good overview of the calculation. A connection to the database is available at any time.

>> You do not have to search for geometry data and gasket characteristics from various other standards.

Type of flange

Type of flange Geometry of flange

Geometry of flange Gasket

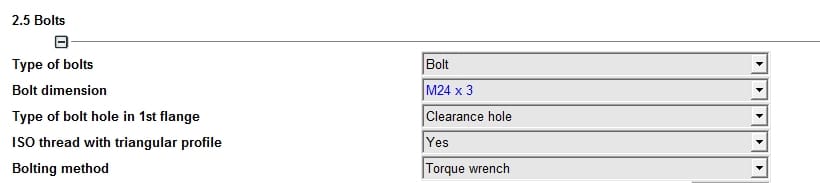

Gasket Bolts

Bolts Loads

Loads

Input mask 1591

Module package 1591

with modules AFLT, SFLA, 1092, VFLN, 1514N and 159N

including Material Database

List price: 2200 EUR plus VAT

|

Printout in German: 220 EUR extra charge

see also:

Dieser Beitrag ist auch verfügbar auf:

Deutsch (German)

Deutsch (German)