Tube bundle vibration analysis program

Until now, the RBSA module has been used for simplified vibration analysis, but it only covers the “vortex excitation” part. The vibration excitation by fluid-elastic instability and turbulence excitation was not investigated. That is why LV has taken over the Good Vibrations program from Prof. Gelbe 2010 and has always adapted it to the current standard.

The program calculates the vibration excitation of the tubes by the following mechanisms:

- Fluid-elastic instability

The individual tubes of the tube bundle are fluid-elastically coupled to each other via the fluid between them, as if by springs. Characteristic is a suddenly very large amplitude increase at a critical speed

The results are Short-term damage due to damage to the tube-tube sheet joint, impact of the tubes against adjacent tubes and impact of the tubes against the baffle plates

- Vortex excitation

The vortex shedding frequency assumes the value of the natural frequency of the pipes. The amplitudes of the individual vibration modes and the weighted maximum amplitude are calculated.

The results are Long-term damage due to impact of the tubes against the baffle plates, damage to the tube-tube sheet joint and fatigue fractures.

- Turbulence excitation.

Long-term damage occurs due to abrasion and wear of the pipes on the deflector plates.

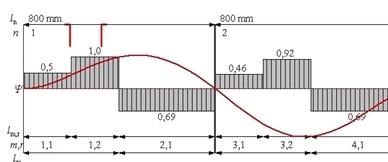

Sectional velocity distribution and Schwingmode

Sectional velocity distribution and Schwingmode

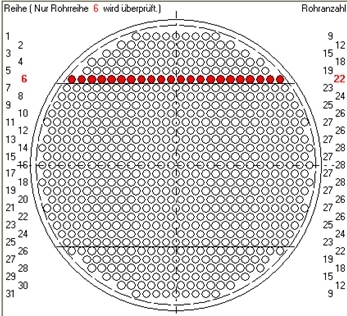

For all 3 excitation mechanisms, the 3 tube rows with the highest degree of risk are specified. A message is automatically displayed if the degree of risk is greater than 85 %.

GV

Stand-alone program GV

- Calculations are performed directly in the GV program.

- Individual inputs

- Consideration of supporting grids and partial supporting grids

The calculation can be performed for the whole tube bundle or only for a particularly endangered row of tubes under the inlet nozzle or in the window zone.

Integrated module GVLV in WTS

The GVLV module is controlled by WTS and cannot be called separately; the values are calculated in GV in the background and transferred to WTS. The documentation takes place within WTS.

Not to be calculated:

-

Exchangers with 2 shell-side passes Longitudinal baffle TEMA Type F

-

Exchangers with disc and doughnut baffles

-

Exchangers with low finned tubes

For these cases, RBSA is called automatically if required and a message is displayed in the WTS in the case of vibration.

GV cannot be used for heat exchangers with Disc and Doughnut Baffles

see also:

Dieser Beitrag ist auch verfügbar auf:

Deutsch (German)

Deutsch (German)