Air coolers – cross-flow heat exchangers

Software for the design of cross-flow heat exchangers with plain or finned tubes.

Possible applications

- air conditioning

Cooler for air e.g. with cold water or evaporating refrigerant

Condensation of air humidity is taken into account.

Air coolers, air conditioners, air-cooled condensers, blower air coolers, air cooling systems, air conditioners, dehumidifiers, cooling units, dry coolers, chillers, water chillers, evaporators (flooded evaporator or pump operation,

- Energy technology

Flue gas heat exchanger for heat recovery (CHP, post-generation, ORC).

Condensation of humidity is taken into account.

air heaters, recuperators, exhaust gas heat exchangers, oil coolers, economizers, waste heat heat exchangers

- Chemical industry

Air cooler for any gases and liquids

Condensers for pure substances with water, brine, thermal oil, refrigerant or other media.

Recirculating coolers, condensers, gas coolers, gas dryers, process gas coolers

If you click on this video we will play the video, load scripts on your device, store cookies and collect personal data. This enables [Google Ireland Limited, Irland] to track activities on the Internet and to display advertising in a target group-oriented manner. There is a data transfer to the USA, which does not have EU-compliant data protection. You will find further information here.

Jmx0O2lmcmFtZSB0aXRsZT0mcXVvdDtMViBXZWJpbmFyIC0gQXVzbGVndW5nIGVpbmVzIEx1ZnRrdWVobGVycyBtaXQgQUMmcXVvdDsgd2lkdGg9JnF1b3Q7Njk2JnF1b3Q7IGhlaWdodD0mcXVvdDs1MjImcXVvdDsgc3JjPSZxdW90O2h0dHBzOi8vd3d3LnlvdXR1YmUuY29tL2VtYmVkL25RYU5Oa3BhV21BP2ZlYXR1cmU9b2VtYmVkJnF1b3Q7IGZyYW1lYm9yZGVyPSZxdW90OzAmcXVvdDsgYWxsb3c9JnF1b3Q7YWNjZWxlcm9tZXRlcjsgYXV0b3BsYXk7IGNsaXBib2FyZC13cml0ZTsgZW5jcnlwdGVkLW1lZGlhOyBneXJvc2NvcGU7IHBpY3R1cmUtaW4tcGljdHVyZSZxdW90OyBhbGxvd2Z1bGxzY3JlZW4mZ3Q7Jmx0Oy9pZnJhbWUmZ3Q7

Design of an air cooler

Design of heat exchangers with rectangular bundles. Different media can be selected in and around the tubes. The heat transfer can be assumed to be single-phase, but also evaporation (only in the tubes) and condensation of pure substances can be calculated.

The available performance reserve and actual outlet temperatures of the media are determined (often deviating from the desired temperatures). The temperature distribution in the cross-flow is determined by means of a complex cell method. You can output the geometry of the tube sheet as a CAD file.

The program automatically determines the material properties for different media. Specific physical properties can be transferred to the program by “Free input”. This also applies to media to be condensed or evaporated.

Substance values and phase equilibria of more than 800 substances and their mixtures are to be determined with the PROPER program as an addition.

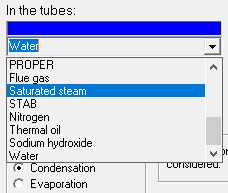

Selection of the medium

Selection of the medium

Geometry

The program considers multi-pass bundles and shells. Tube pitch and arrangement are freely selectable. A variety of tube geometries is included: Plain tubes, circular, spiral and rectangular fins, lamellas, internal fins, twisted tube inserts, corrugated tubes. Shells may be round or rectangular.

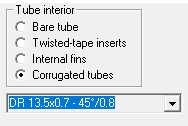

Tube interior

Tube interior

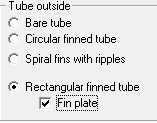

Tube outside

Tube outside

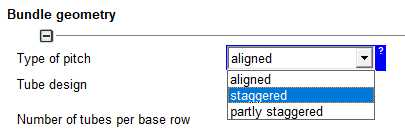

Tube arrangement

Tube arrangement

heat transfer

When cooling air or flue gas, the condensation of moisture on the cold wall is taken into account. The heat transfer is determined according to the approach in [1] and the amount of water or the outlet moisture is calculated. Warnings are issued for wall temperatures below freezing as well as for very large quantities of water. Calculations of condensation processes of pure substances in the tubes and in the shell space are carried out according to the approaches of the VDI Heat Atlas [2]. During evaporation, the heat transfer is calculated section by section.

Evaporation and condensation can be calculated completely or partially.

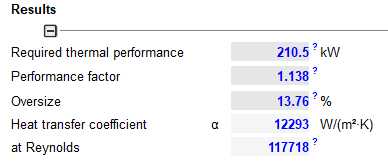

Result

Result

Price of standard version: on request

|

Literature

[1] Verfahrenstechnische Berechnungsmethoden, Teil 1, VCH Weinheim

[2] VDI Heat Atlas

see also:

Dieser Beitrag ist auch verfügbar auf:

Deutsch (German)

Deutsch (German)